Everything is going green these days. I thought it might be a good idea to convert a regular radio controlled car into a solar powered car. This would mean hours of fun without the need to change the batteries and would also make a good school science project. Here is what you will need:

- A radio controlled car

- Appropriate Solar Panel

- One diode

- Soldering Iron

- Screw driver

- Wires for connection

The car:

You can choose any radio controlled car. It would however be a good to idea to check the available solar panel first. I chose a car that uses 4x1.5V AA batteries. This would add up to 6V.

The Solar Panel:

Since the car requires 6V I bought a small 6 volt panel from eBay.

The Project:

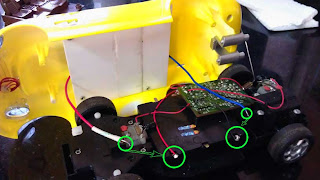

The first part involves taking the car apart. Most probably you would find the appropriate screws right below the car. The one I bought had four screws. Once these were unscrewed the top part could be easily taken off revealing the electronic circuit.

You will find two wires [ mostly red and black] coming out of the battery box. The red is the positive and the black is the negative wire. These are the two points that we will connect our solar line to. The car that I used had head lights which went on when the car moved. This was directly connected across the motor that drove the wheels. To save power I disconnected the head lights.

Some radio controlled cars come with rechargeable batteries that are not AA or AAA but the connection would still remain the same. Our aim is to connect the output of the solar panel to the battery terminals.

The under carriage of the car houses the battery box , open it and replace the AA batteries with rechargeable AA batteries. Your car might come with non-rechargeable batteries like mine did. Make sure that you have rechargeable batteries in the box or this project wont work. I took off the seats and the wind shield to facilitate the fixing of the panel there. A piece of acrylic was cut out to cover the empty space and prevent dust and moister from directly falling on to the circuit below.

Cut two pieces of wire, red [+] and blue [-] and the same is soldered on to the + and - terminals of the panel. At the far end of the red [positive] wire the diode is soldered. The diode has a silver ring to denote the negative side of the diode and the other side is positive. The positive side of the diode is soldered on to the positive wire coming from the panel.

The acrylic piece has screw holes drilled at the exact places where the seat fixture had screws. So the same screws were used to securely fasten the acrylic panel on to the car body. I then used rubber based glue to attach the panel to the body of the car.

Make sure that that there are no batteries in the battery box while you do the following. The bare end of the red wire with the diode [ silver ring end] is soldered to the positive terminal of the battery box and the blue wire to the negative side. It would be good to recheck the connection before popping the batteries back in.

Explanation for the School Science Project:

A photo voltaic cell converts the light from the sun into electricity. The panel mounted on the car produces electricity that charges the on board battery bank. The diode is a component that lets current flow only in one direction. When the panel is not producing current there is a possibly for the power from the battery to drain out into the panel. The diode is kept to prevent the reverse flow of current from the battery into the panel. We could say that this is a very simple charge controller. In larger electric cars that are seen on the street, a more sophisticated charge controller is used to control the charging of the battery in the car. The components in any solar car would be the, solar panel > charge controller > battery. The rest of the circuitry would control the motor drive. This same technology one scaled up can be used to build bigger solar powered cars.